Approaches to recycled content allocation in LCA

Recycled content allocation

Understanding recycling within Life Cycle Assessment (LCA) is becoming increasingly relevant for manufacturers. The use of recycled materials is now more prevalent than ever and there is strong push toward improving recycling rates after disposal. Therefore, if an LCA-study involves recycling of materials, a methodological approach for the recycled content allocation of the burdens and benefits needs to be chosen. The choice of approach is up to the practitioner, so long as it aligns with the goal and scope of the study. This choice will impact the interpretation of the LCA results, so it is important to understand what each approach means, and which is best suited to your study.

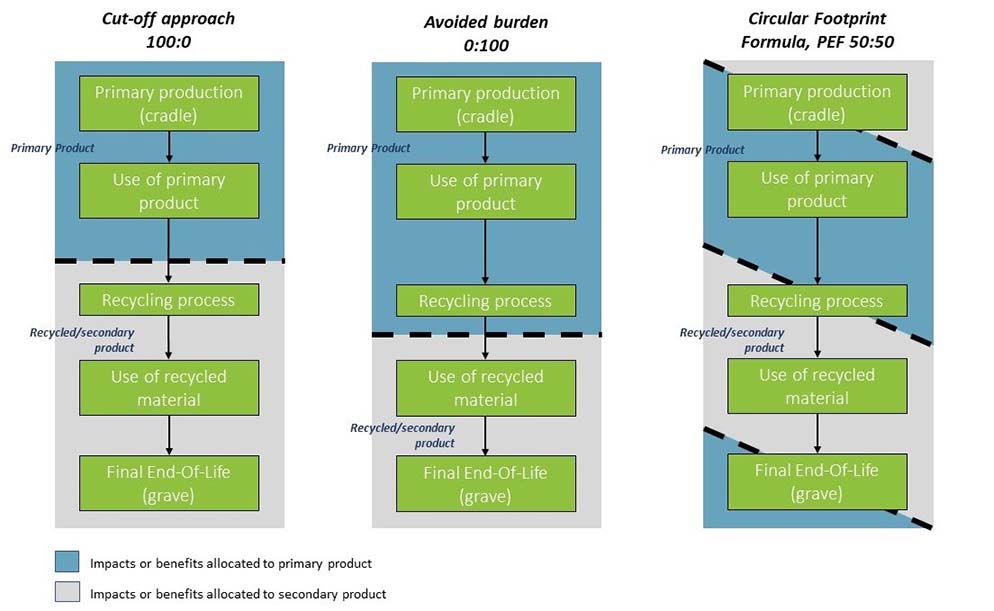

There are several approaches that can be followed for recycled content allocation, including the cut-off approach, avoided burden approach, and the circular footprint formula. The diagram outlines each approach, and we will discuss them in more detail below.

Figure 1: Overview of the approaches to allocation of burden and benefit of recycled materials in LCA. Image adapted from Toward sustainable development through circular economy, Corona et al., (2019).

1. Recycled Content, or cut-off approach

Also known as the 100:0 approach, the recycled content, or cut-off, approach states that the primary user carries the environmental impacts of the production process (this follows the “polluter pays” principle). If the material is then recycled at the End-of-Life, the primary user does not receive the environmental benefit (credit) for the provision of these recycled materials to the secondary user. Instead, the secondary user receives the material without the environmental impacts (burdens) of its primary production process and carries only the environmental impacts of the recycling processes.

For example, when steel is recycled, the steel is received burden free by the secondary user at the point of recycling. Once recycled, the secondary steel carries the burden of the recycling process, as well as any steps required to make the steel ready for use in its secondary life cycle. The primary producer of the steel does not receive any credit for the secondary use of the product.

This approach is said to stimulate the use of a higher proportion of recycled material within a product as it carries a lower environmental impact than the use of virgin/primary materials. It is generally preferred in cases where there is a high supply of recyclable materials and a low demand. It is also considered easy to follow and communicate.

2. End-of-life recycling, avoided burden, or closed-loop approach

Also known as the 0:100 approach, this approach operates under the assumption that the recycled material input (secondary material) replaces a quantity of virgin material in the secondary life cycle. Within this approach, the benefits of recycling are credited to the manufacturing of the primary product. This means that the impact of the recycling process (for example, energy use) is allocated to the primary life cycle, as well as the benefit of avoiding the impact associated with the use of virgin materials by the secondary producer. At the same time the full burden associated with virgin material use will be assigned to the secondary life cycle. This generally applies when there is a low supply of recyclable materials that are in high demand. The avoided burden method is said to stimulate the production of recycled material and is preferred by some industries (i.e., the metal industry).

Looking again at the example of steel, employing the avoided burden approach would reduce the environmental impacts attached to the manufacture of primary steel significantly as this is where the credit for recycling is assigned. The environmental burdens from primary manufacture are then instead transferred to the product’s final life cycle.

3. The Circular Footprint Formula

The Circular Footprint Formula is a method taken from the European Commission PEF and OEF framework which addresses reused and recycled content, as well as diverse End-of-Life scenarios in LCA. Depending on the supply and demand of the recycled material, the burdens of recycling are divided between the primary system and secondary system.

In principle, the following rationale can be applied:

- High supply of recyclable materials and a low demand: the formula focusses on recycled content

- Low supply of recyclable materials and a high demand: the formula focusses on recovery at End-of-Life.

Within the PEF guidance, this is referred to as “the A factor”, where an A factor of 1 would reflect the 100:0 approach, and an A factor of 0 would reflect the 0:100 approach. For PEF studies, the A factor will always fall within the range of 0,2 – 0,8. A value of 0,2 indicates a low supply of recyclable materials and high market demand, while 0,8 indicates a high supply of recyclable materials and a low market demand. Specific values are provided for PEF studies, but if none are available, a default value of 0,5 is used.

Which method should you choose?

Currently there is no consensus on the definitive approach to recycled content allocation. However, it is essential to note that certain standards and guidelines recommend specific methodologies.

At Ecomatters we can assist you in determining the type of LCA study best suited to your goals, and as such, the most suitable approach for recycled content allocation. Find out more about how we work with the Life Cycle Thinking approach, or contact us directly.

LCA services

Contact us

Max Sonnen

Brienne Wiersema

Related case studies

Ecomatters supported AkzoNobel in their 4-Dimensional Profit and Loss Accounting…

Call with our consultant

Do you want to know more about how we can help? Schedule a call with one of our consultants to ask your questions.